Crafted with extraordinary attention to detail, our latest Mosaic Grip edition pen represents the pinnacle of sophistication and functionality. In this journal post, we're excited to reveal the precise process behind the creation of this exceptional edition, showcasing the dedication and expertise involved at every stage.

At the core of our Mosaic Grip design is precision laser engraving, a technique that not only enhances the pen's aesthetic appeal but also elevates the writing experience by providing a tactile grip for optimal control and comfort.

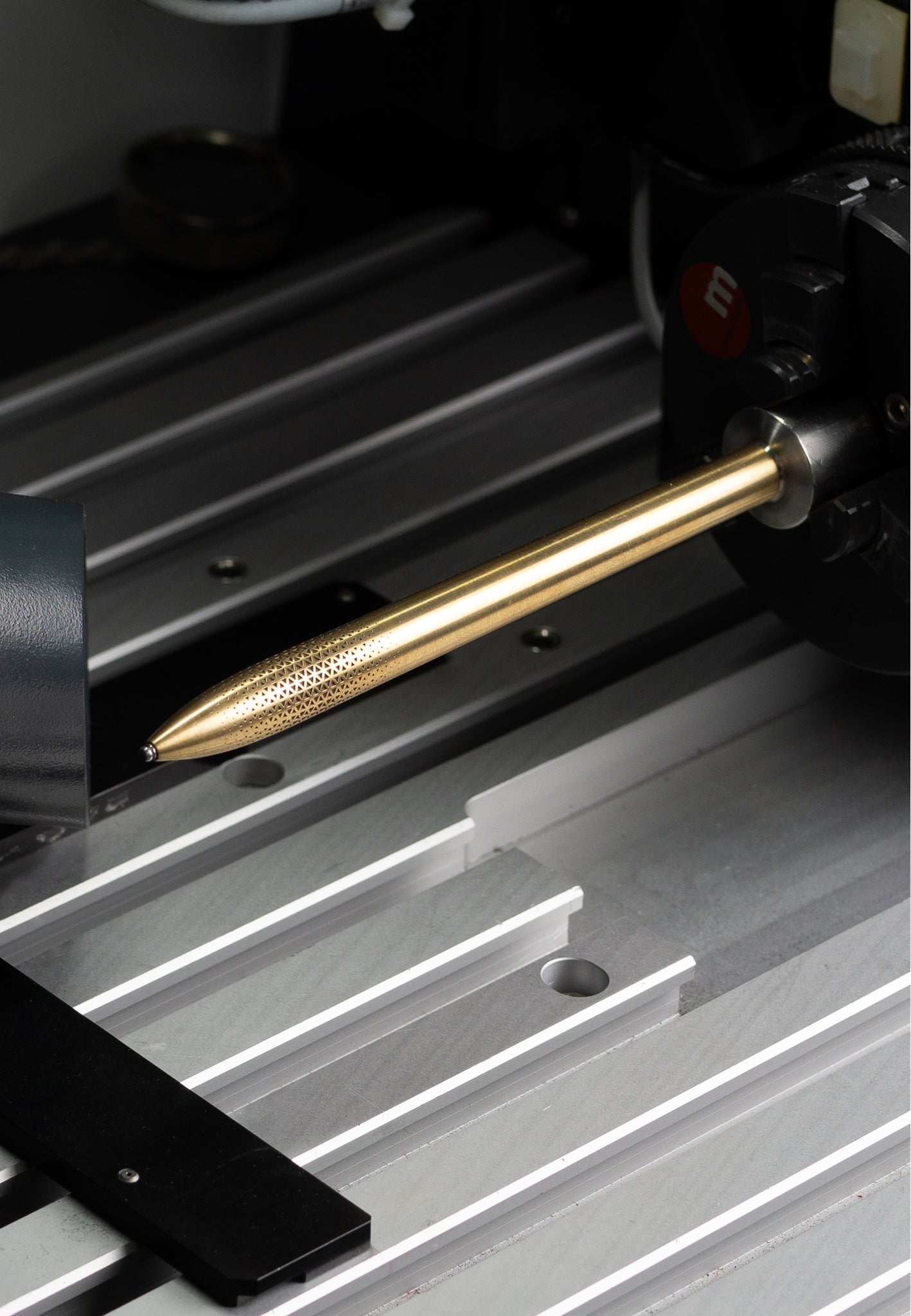

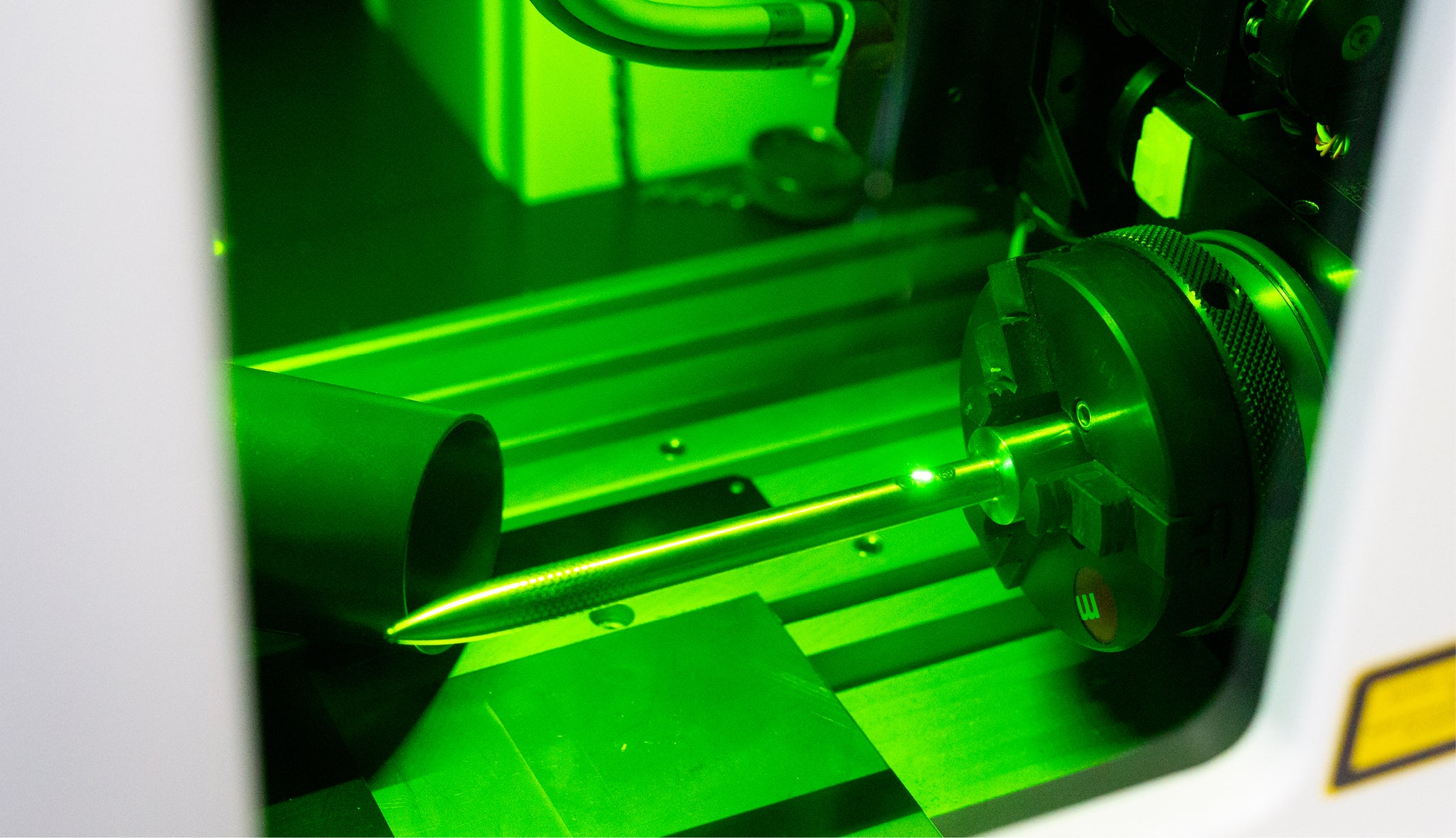

The process begins with our state-of-the-art precision laser machine, a specialised Fibre Laser tailored for use in the jewellery and technology industries. This high-precision laser allows us to engrave intricate mosaic patterns with microscopic detail and unmatched accuracy.

Unlike traditional engraving methods, our laser engraving priorities accuracy over speed. Layer by layer, the laser delicately removes material from the pen's surface, ensuring a sharp edge that seamlessly flows across the body. Each pass of the laser is carefully planned to maintain a smooth finish and prevent the formation of lines or grooves.

To guarantee consistency and precision, the pen is securely mounted onto a rotational axis using a specially designed mandrel made from tool steel. This setup minimizes any deviation as the axis rotates, ensuring precise engraving around the entire circumference of the pen.

As the laser operates, producing heat and debris, a sophisticated extraction system swiftly removes all fumes and particles, creating a clean and safe working environment.

Once the intricate mosaic pattern is engraved to perfection, a series of hand-finishing processes begin. The pen is delicately removed from the mandrel and cleansed in an ultrasonic tank with a specialized cleaning solution, ensuring a debris-free surface.

Next, our skilled artisans polish the pen by hand, using progressively finer abrasive cloths to achieve a brilliant shine. To further enhance its appeal and durability, the surface undergoes a light texturing process, creating a satin spun effect that minimizes fingerprints and preserves its timeless elegance.

From start to finish, each Mosaic edition pen undergoes over three hours of meticulous craftsmanship, complemented by extensive research, design, and development. The result is a masterpiece that seamlessly combines form and function, embodying timeless elegance and unwavering quality.

In conclusion, our Mosaic Grip edition pen is more than just a writing instrument—it's a testament to our enduring commitment to craftsmanship and innovation. With its exquisite design and meticulous attention to detail, it's destined to become a cherished companion for years to come.

Stay tuned for more stories!

Chris & Marta